Amorphous alloy dry-type transformer

The SCBH15 series amorphous alloy dry-type transformer is a new type of low-loss energy-saving distribution transformer. This product combines the technological advantages of amorphous alloy transformers and traditional epoxy resin cast dry-type transformers, and adopts a new structural form.

- Product Description

-

Amorphous alloy dry-type transformer Overview

Product Introduction

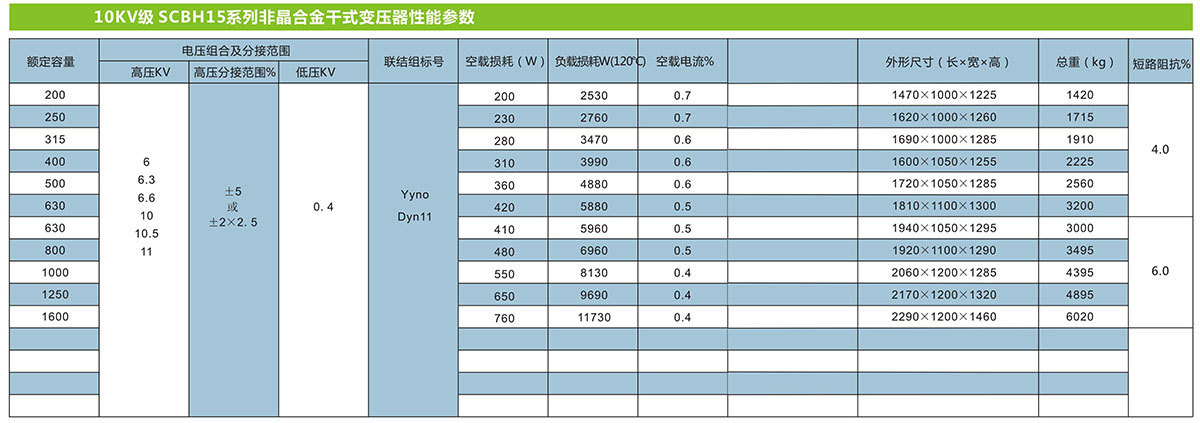

The SCBH15 series amorphous alloy dry-type transformer is a new type of low-loss energy-saving distribution transformer. This product combines the technological advantages of amorphous alloy transformers and traditional epoxy-cast dry-type transformers, adopting a brand-new structural form. The SCBH15 series amorphous alloy dry-type transformer has the characteristics of low loss, especially no-load loss, which is 70% lower than that of conventional 10 series dry-type transformers. This product also has the advantages of compact structure, beautiful appearance, low noise, low temperature rise, strong overload capacity, stable electrical performance, and convenient maintenance.

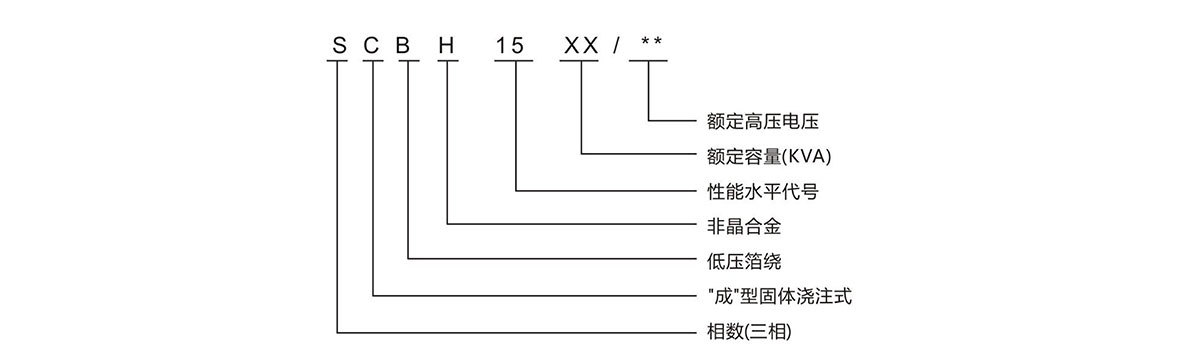

Model Description

Conditions of Use

Altitude ≤1000m, ambient temperature: -25°C~+40°C. Indoor type transformers with air natural cooling and forced air cooling must ensure good ventilation. When the transformer is installed in a basement or other environment with poor ventilation, additional heat dissipation and ventilation devices must be added. The protection level includes IP00, IP20, and IP23 types. When the altitude is >1000 meters, users should specify the altitude, and the design will adjust the temperature rise parameters.

Product Features

★Low Loss and Energy Saving: Using amorphous alloy, a soft magnetic conductive material with isotropic properties, the magnetization power is small, the resistivity is high, and the eddy current loss is small. The no-load loss and no-load current of the core made of amorphous alloy material are very low, only about 1/3 of that of silicon steel sheets. The no-load loss of the transformer is reduced by about 75% compared to the GB/T10228 standard. Operating costs can be greatly reduced, and the energy-saving effect is very significant.

★Strong Corrosion Resistance: The amorphous alloy core is fully encapsulated with resin and high-temperature silicone gel, effectively preventing rust and the shedding of amorphous alloy fragments, thus effectively protecting the core and coils.

★Low Noise: To reduce product operating noise, reasonable working magnetic flux density is selected during product design, the core and coil structure is improved during product processing, and special noise reduction materials are used, etc. The noise of the amorphous alloy dry-type transformer is far lower than the requirements of national standard JB/T10088.

★Strong Short-Circuit Resistance: The product adopts a three-phase five-column structure, and the core is protected by a frame structure on all sides, with a compact and reasonable structure. The amorphous alloy dry-type transformer is the first in China to pass the sudden short-circuit test.

★Low Temperature Rise, Long Service Life: The product has a low temperature rise and strong heat dissipation capacity. It can operate at 130% rated load under forced air cooling conditions. A complete temperature control protection system can be optionally configured to provide reliable protection for the safe operation of the transformer.

-

High-efficiency energy conversion design

The power transformer adopts high-magnetic silicon steel sheets and optimized winding structure to achieve an energy conversion efficiency of more than 98.5%, and the no-load loss is 30% lower than that of traditional products. The specially designed cooling channel keeps the temperature rise within 45K to ensure continuous and stable operation. -

Intelligent monitoring system

The transformer with integrated IoT technology is equipped with 12 real-time monitoring points, which can accurately collect key parameters such as temperature, oil level, vibration, etc., and realize abnormal warning through the cloud platform, and the fault response time is shortened to within 15 minutes. -

Environmentally friendly insulation solution

The new plant ester insulating oil is completely biodegradable, with a flammability of more than 320℃. Combined with specially treated insulating paper, the environmental protection level of the transformer is raised to the highest standard, and the service life is extended to 30 years.

-