Unenclosed dry-type transformer

The SG(B)10 series of unsealed dry-type transformers boasts excellent weather resistance, including moisture and salt resistance. They offer safe and reliable operation at high temperatures, with low partial discharge, low noise, high heat dissipation efficiency, and strong overload capacity. They represent a new generation of green and environmentally friendly dry-type transformers.

- Product Description

-

Unenclosed dry-type transformer Overview

Product Introduction

The SG(B)10 series non-encapsulated dry-type transformers have excellent weather resistance, including moisture and salt resistance. They operate safely and reliably at high temperatures, with low partial discharge and noise, high heat dissipation efficiency, and strong overload capacity. They are a new generation of green and environmentally friendly dry-type transformers. They are most suitable for use in high-temperature and high-pollution areas such as hydropower plants, thermal power plants, steel mills, chemical plants, and mines in China.

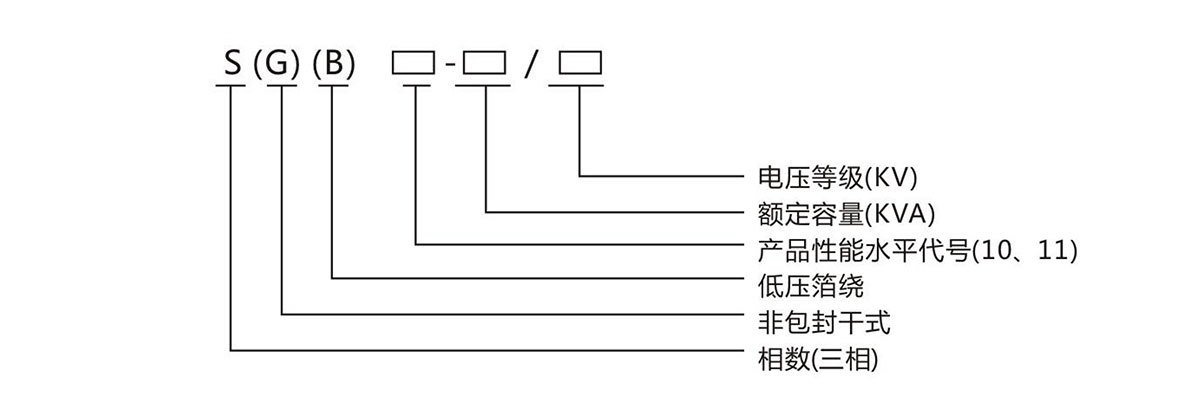

Model Description

Conditions of Use

Altitude ≤1000m, ambient temperature: -25°℃~+40℃. For indoor air-cooled and forced-air-cooled transformers, good ventilation must be ensured. If the transformer is installed in a basement or other environment with poor ventilation, additional heat dissipation and ventilation devices must be added. Protection levels include IP00, IP20, and IP23.

When the altitude is >1000 meters, the user should specify the altitude; the design will adjust the temperature rise parameters.

Product Features

SG(B)10/11 uses DuPont NOMEX paper as the basis for a system that maintains excellent electrical and mechanical properties throughout the transformer's lifespan. NOMEX paper is resistant to aging, shrinkage, and compression, and its high elasticity ensures that the coil remains tightly structured even after years of use; it can also withstand short-circuit pressure.

★H-class insulation: Dry-type transformers have insulation heat resistance grades of B, F, H, and C. The heat-resistant temperatures are 130℃, 155℃, 180℃, and 220℃ respectively. This product uses DuPont NOMEX as the insulation material, reaching H-class insulation, with key parts reaching C-class.

★Safety: All insulation materials in SG(B)10/11 products are non-combustible, non-explosive, and non-toxic. Their combustible material is less than 10% of epoxy-cast products. Under 800℃ high temperature and long-term combustion, almost no toxic smoke is produced, overcoming the defect of epoxy-cast dry-type transformers producing a large amount of toxic gas during combustion. SG(B)10/11 products are superior in places with high safety requirements, high humidity, heat, and poor ventilation, such as subways, ships, chemical plants, and metallurgy.

★Reliability: The special coil design, process, and materials of SG(B)10/11 products make them have excellent three-proof performance (moisture-proof, mildew-proof, and salt-spray-proof), and can withstand thermal shock, with very low partial discharge.

★Environmental Protection: SG(B)10/11 products do not pollute the environment during manufacturing, transportation, storage, and operation. After the lifespan of SG(B)10/11 products, they can be decomposed and recycled to meet customer needs, overcoming the defect that epoxy resin-cast dry-type transformers cannot be decomposed and pollute the environment after their lifespan due to the resin and glass fiber solidifying and fusing into a group. SG10 products have low noise and are suitable for use in densely populated upscale communities or other modern locations.

★Strong Overload Capacity: SG(B)10/11 products adopt new structures, new materials, and new processes, with good heat dissipation conditions, long thermal life, and extremely strong overload capacity. They can operate safely and reliably under 130% overload, and can operate at full load for a long time without forced air cooling in IP23 or IP45 environments.

★Smaller Size and Lighter Weight: SG(B)10/11 products use DuPont NOMEX paper as the main insulation material and use it as a mixed insulation system at the hottest parts of the transformer. Compared with epoxy-cast transformers of the same capacity, the volume and weight are reduced by 30%.

-

High-efficiency energy conversion design

The power transformer adopts high-magnetic silicon steel sheets and optimized winding structure to achieve an energy conversion efficiency of more than 98.5%, and the no-load loss is 30% lower than that of traditional products. The specially designed cooling channel keeps the temperature rise within 45K to ensure continuous and stable operation. -

Intelligent monitoring system

The transformer with integrated IoT technology is equipped with 12 real-time monitoring points, which can accurately collect key parameters such as temperature, oil level, vibration, etc., and realize abnormal warning through the cloud platform, and the fault response time is shortened to within 15 minutes. -

Environmentally friendly insulation solution

The new plant ester insulating oil is completely biodegradable, with a flammability of more than 320℃. Combined with specially treated insulating paper, the environmental protection level of the transformer is raised to the highest standard, and the service life is extended to 30 years.

-