Amorphous alloy distribution transformer

Amorphous alloy cores have the characteristics of high magnetic induction, low loss (equivalent to 1/3-1/5 of silicon steel sheets), low coercive force, low excitation current, and good temperature stability. Transformers manufactured with amorphous alloy cores have no-load losses that are 35% lower than current S11 products.

- Product Description

-

Amorphous alloy distribution transformer Overview

Product Introduction

Amorphous alloy iron cores have characteristics such as strong magnetic induction, low loss (equivalent to 1/3-1/5 of silicon steel sheets), low coercive force, low exciting current, and good temperature stability. Transformers manufactured with amorphous alloy iron cores have no-load losses that are 35% lower than current S11 products, and the no-load current is 60-70% lower than the S11 series, resulting in significant energy savings. They are especially suitable for users with low load rates, such as those in vast rural areas and developing regions.

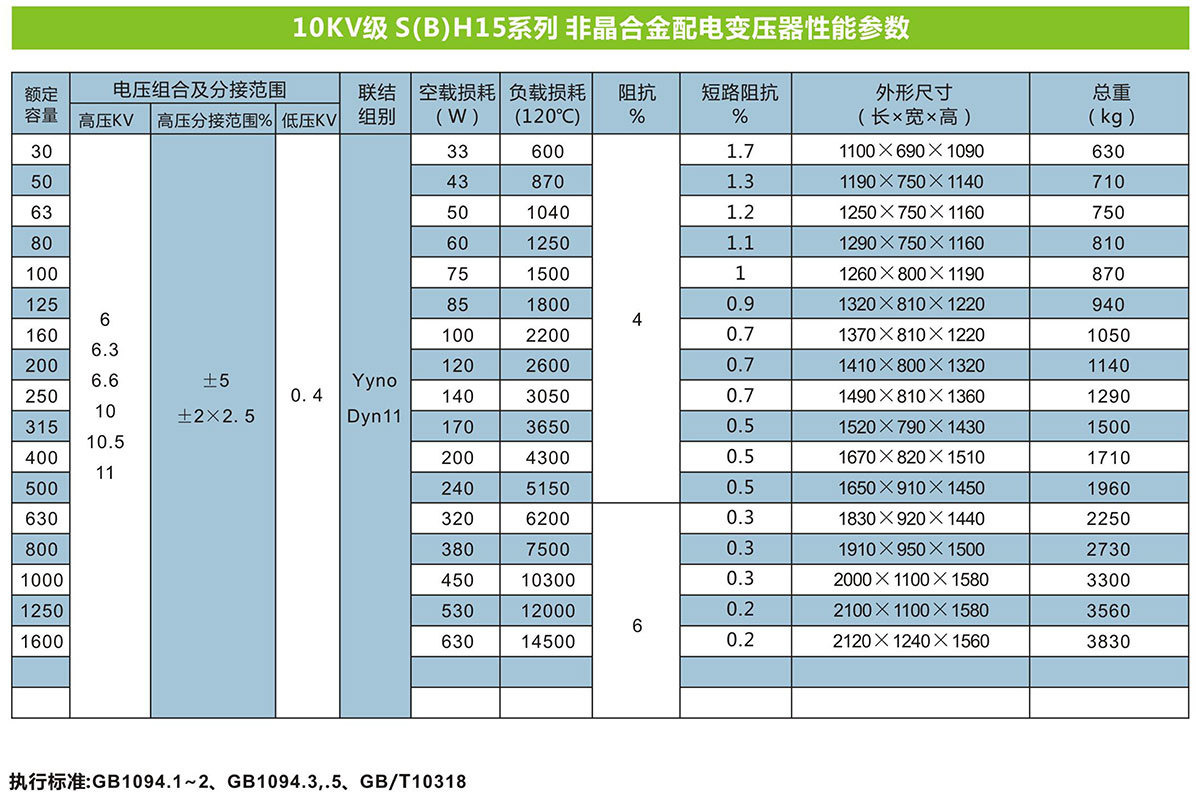

S(B)H15 type amorphous alloy products use single-frame or three-phase five-column wound cores. The core is clamped using a thin-plate formed frame structure. The low-voltage coil is foil-wound, resulting in low loss and strong short-circuit resistance. The structure is advanced and reasonable, and the overall performance indicators have reached the world's advanced level.

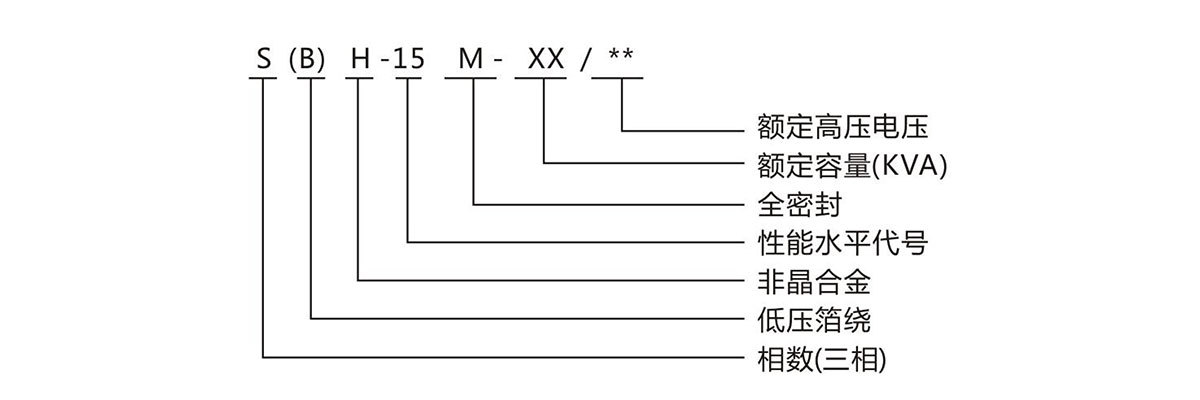

Model Description

Operating Conditions

Altitude not exceeding 1000m, indoor or outdoor

Maximum ambient temperature +40℃, maximum daily average temperature +30°C

Maximum annual average temperature +20°℃, minimum temperature -25°℃

Transformers can be provided for operation under special conditions according to user requirements.

Product Features

◆The transformer core is made of amorphous alloy strip material, and the no-load loss is reduced by about 35% compared to the S11 transformer.

◆The transformer low voltage uses a copper foil coil, enhancing the transformer's ability to withstand short circuits.

◆The transformer connection group uses Dyn11, reducing the impact of harmonics on the power grid and improving power quality.

◆The oil tank and cover are welded into a fully sealed structure, extending the service life; maintenance-free.

◆The transformer uses vacuum oil injection to completely remove air from the coils, ensuring stable insulation performance.

◆Before delivery, each transformer undergoes a full-wave lightning impulse test with a peak voltage 25% higher than the national standard, ensuring safe and reliable operation of the transformer.

-

High-efficiency energy conversion design

The power transformer adopts high-magnetic silicon steel sheets and optimized winding structure to achieve an energy conversion efficiency of more than 98.5%, and the no-load loss is 30% lower than that of traditional products. The specially designed cooling channel keeps the temperature rise within 45K to ensure continuous and stable operation. -

Intelligent monitoring system

The transformer with integrated IoT technology is equipped with 12 real-time monitoring points, which can accurately collect key parameters such as temperature, oil level, vibration, etc., and realize abnormal warning through the cloud platform, and the fault response time is shortened to within 15 minutes. -

Environmentally friendly insulation solution

The new plant ester insulating oil is completely biodegradable, with a flammability of more than 320℃. Combined with specially treated insulating paper, the environmental protection level of the transformer is raised to the highest standard, and the service life is extended to 30 years.

-