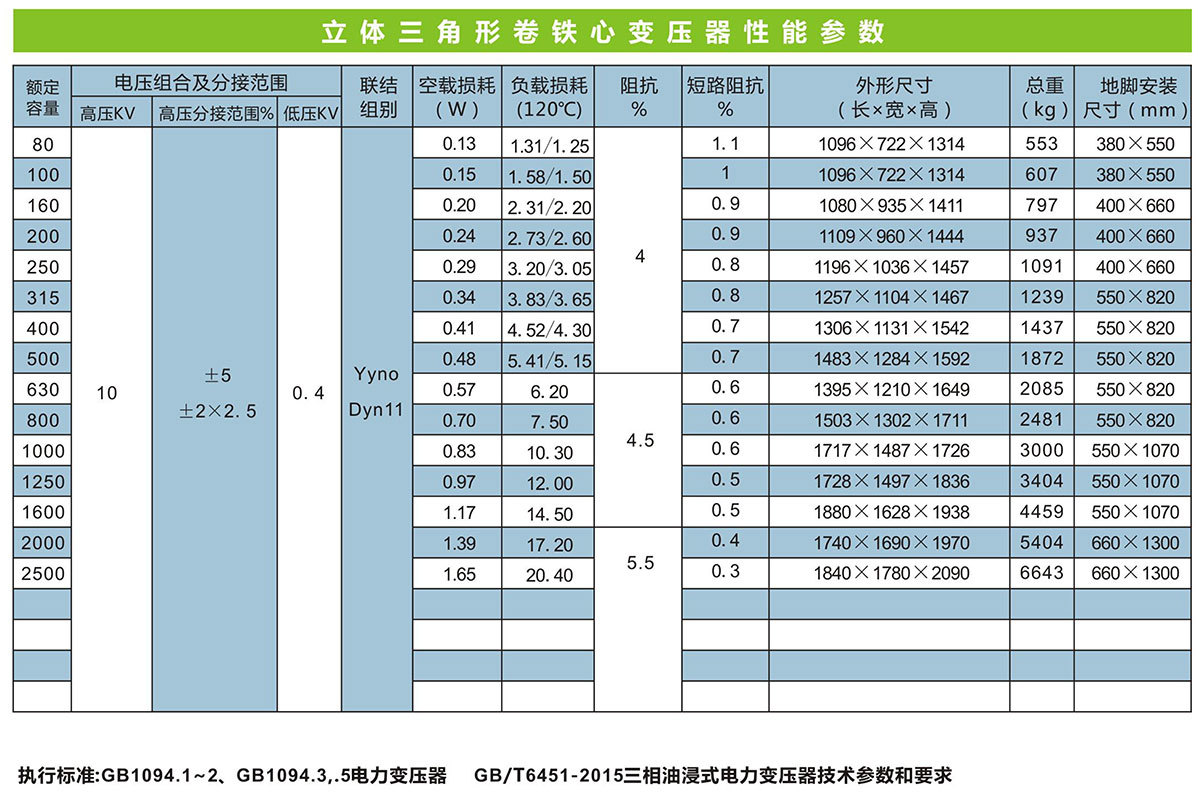

Three-dimensional triangular core transformer

This product breaks through the traditional planar structure and adopts a three-phase symmetrical three-dimensional structure. Its magnetic circuit has no air gap, the windings are tight, and the three cores are arranged in an equilateral triangle three-dimensionally, resulting in zero waste during processing and cutting.

- Product Description

-

Three-dimensional triangular core transformer Overview

Product Introduction

This product breaks through the traditional planar structure and adopts a three-phase symmetrical three-dimensional structure. Its magnetic circuit has no air gap, the windings are tight, and the three cores are arranged in an equilateral triangle, resulting in zero material waste during processing. This series of products not only saves materials and reduces losses, but also has low operating noise, promoting China's energy conservation and environmental protection policies, and playing an important role in national resource conservation and environmental protection.

Model Description

Conditions of Use

Altitude not exceeding 1000m, indoor or outdoor

Maximum ambient temperature +40°℃, maximum daily average temperature +30°C

Maximum annual average temperature +20℃, minimum temperature -25°℃

Transformers operating under special conditions can be provided according to user requirements.

Product Features

This series of products features energy saving and consumption reduction, noise reduction; material saving and cost reduction; three-phase balance, stable quality and improved production efficiency.

★ Compared with S11 transformers of the same capacity, no-load losses are reduced by more than 25%, no-load current is reduced by 70%, and noise is reduced by 7dB(A)~10dB(A).

★ The three-dimensional triangular core consists of three cores arranged in an equilateral triangle. The magnetic path lengths of the three cores are completely consistent and the shortest, and the losses of the three cores are consistent, thus achieving three-phase balance.

-

High-efficiency energy conversion design

The power transformer adopts high-magnetic silicon steel sheets and optimized winding structure to achieve an energy conversion efficiency of more than 98.5%, and the no-load loss is 30% lower than that of traditional products. The specially designed cooling channel keeps the temperature rise within 45K to ensure continuous and stable operation. -

Intelligent monitoring system

The transformer with integrated IoT technology is equipped with 12 real-time monitoring points, which can accurately collect key parameters such as temperature, oil level, vibration, etc., and realize abnormal warning through the cloud platform, and the fault response time is shortened to within 15 minutes. -

Environmentally friendly insulation solution

The new plant ester insulating oil is completely biodegradable, with a flammability of more than 320℃. Combined with specially treated insulating paper, the environmental protection level of the transformer is raised to the highest standard, and the service life is extended to 30 years.

-